TITANIUM TI-6AL-4V GRADE 5, also known as TI64 or UNS R56400, is a high-strength titanium alloy commonly used in aerospace, medical, and industrial applications. It is recognized under F1472 and ASME SB 265.

This alloy consists of titanium with 6% aluminum and 4% vanadium, providing exceptional strength-to-weight ratio, corrosion resistance, and high-temperature stability. It is a go-to material for applications where lightweight and durable materials are essential.

Titanium TI-6AL-4V Sheet | Plate

Titanium TI-6AL-4V sheets and plates are available in various thicknesses and sizes. These materials are ideal for aerospace components, marine applications, and other high-strength, lightweight structures.

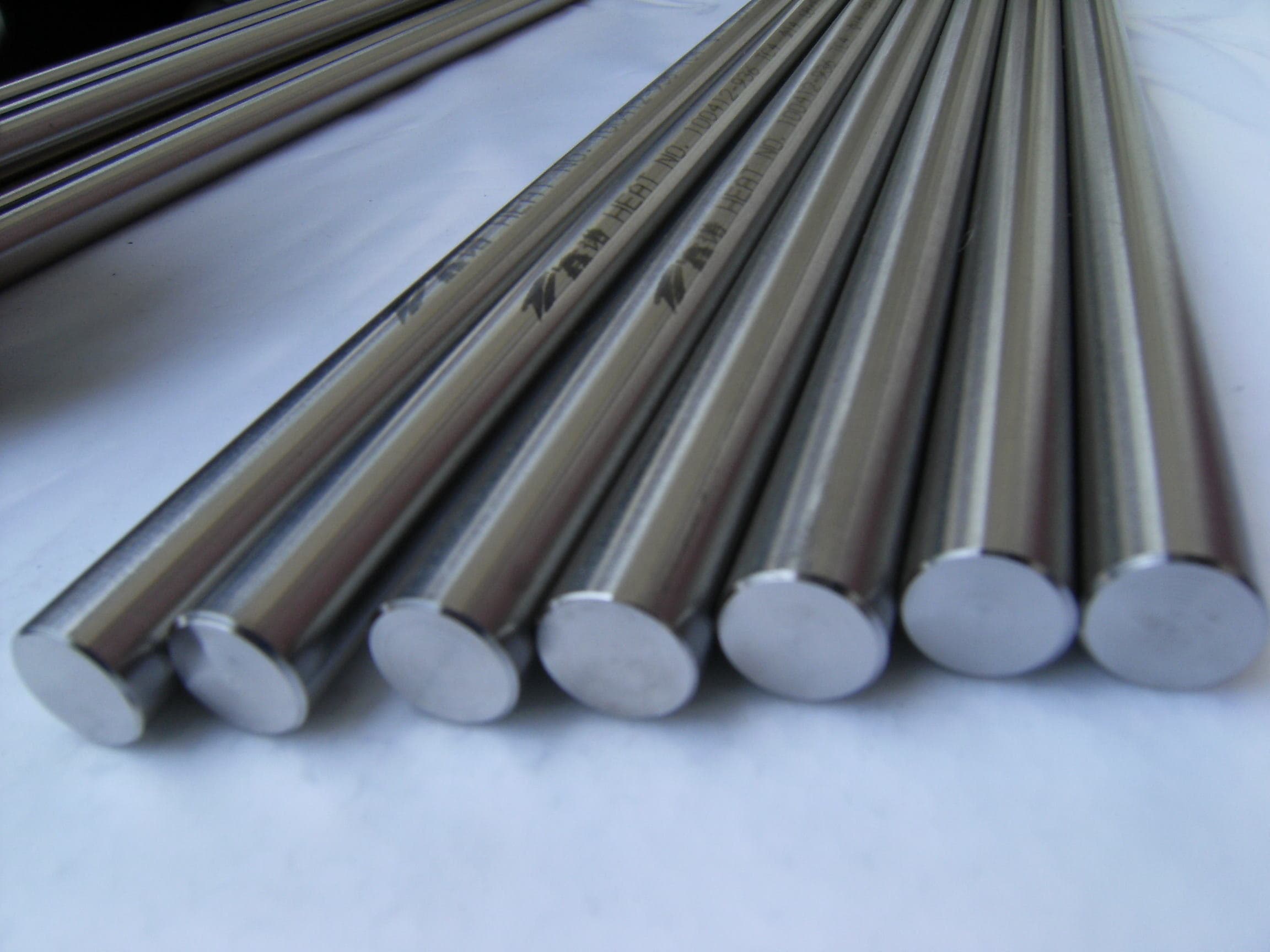

Titanium TI-6AL-4V Round Bar | Rod

Titanium TI-6AL-4V round bars and rods come in different diameters and lengths. These products are used for precision machining and manufacturing components requiring high strength and durability.

Titanium TI-6AL-4V Strip | Coil

Available in strips and coils, Titanium TI-6AL-4V is suitable for flexible applications where strength and lightweight properties are crucial, such as for producing gaskets, seals, and structural components.

Titanium TI-6AL-4V Applications

- Widely used for aircraft components, including structural elements and fasteners, due to its high strength and low weight.

Titanium TI-6AL-4V Properties

- Tensile Strength: High tensile strength of approximately 1300 MPa, making it suitable for load-bearing applications.

- Density: About 4.43 g/cm³, providing a favorable strength-to-weight ratio.

- Thermal Conductivity: Low thermal conductivity, which helps in applications requiring thermal insulation or stability.

- Corrosion Resistance: Excellent resistance to corrosion in many environments, including acidic and chloride-rich conditions.

Machining Titanium TI-6AL-4V

- Cutting: Use carbide tools or high-speed steel for cutting Titanium TI-6AL-4V. Techniques such as water jet cutting or laser cutting are recommended for precision work.

- Drilling: Employ carbide or cobalt drills for drilling Titanium TI-6AL-4V. Proper cooling and lubrication are essential to maintain tool life and ensure accurate drilling.

- Turning: Carbide inserts are preferred for turning Titanium TI-6AL-4V. Consistent cutting speeds and high-pressure cooling are crucial for achieving optimal results.

- Milling: Milling operations should use carbide end mills with adequate cooling to manage heat and maintain precision during processing.

- Grinding: For grinding Titanium TI-6AL-4V, use diamond or CBN wheels to achieve precise tolerances and a high-quality surface finish. Adequate cooling is necessary to prevent overheating and maintain dimensional accuracy.

Chemical Composition

- Carbon (C): Max 0.08%

- Oxygen (O): Max 0.20%

- Nitrogen (N): Max 0.05%

- Hydrogen (H): Max 0.125%

- Aluminum (Al): Min 5.5%, Max 6.75%

- Vanadium (V): Min 3.5%, Max 4.50%

- Iron (Fe): Max 0.40%

- Yttrium (Y): Max 0.005%

- Titanium (Ti): Balance

| Material | Form | Size Inches | SKU Number |

|---|---|---|---|

| Titanium TI-6AL-4V | Sheet | Thickness: 0.020" to 0.500"; custom widths and lengths | TITANIUM64-SHEET-0.125-12x12 |

| Titanium TI-6AL-4V | Plate | Thickness: 0.500" and up; custom sizes | TITANIUM64-PLATE-0.750-24x24 |

| Titanium TI-6AL-4V | Bar/Rod | Diameter: 0.250" to several inches; length up to 36" or more | TITANIUM64-BAR-1-36 |

| Titanium TI-6AL-4V | Tube/Pipe | Diameter: 0.5" to several inches; custom wall thickness | TITANIUM64-TUBE-1-0.125 |

| Titanium TI-6AL-4V | Wire | Diameter: 0.010" to 0.250"; often supplied in coils | TITANIUM64-WIRE-0.050-100 |

| Titanium TI-6AL-4V | Custom Fabrications | Custom dimensions and shapes as required | TITANIUM64-CUSTOM-FAB-001 |