Supra 510, also known as Alloy 50 or Ni50Fe, is a nickel-iron alloy renowned for its very low coefficient of thermal expansion. This alloy is recognized under various standards including UNS N05050, DIN 1.3917, and ASTM A753. These designations reflect its adherence to international specifications and its utility in precision applications where minimal thermal expansion is crucial.

Supra 510 is composed of approximately 50% nickel and the remainder iron. This composition ensures exceptionally low thermal expansion, making it ideal for high-precision applications that require stability and accuracy across varying temperatures.

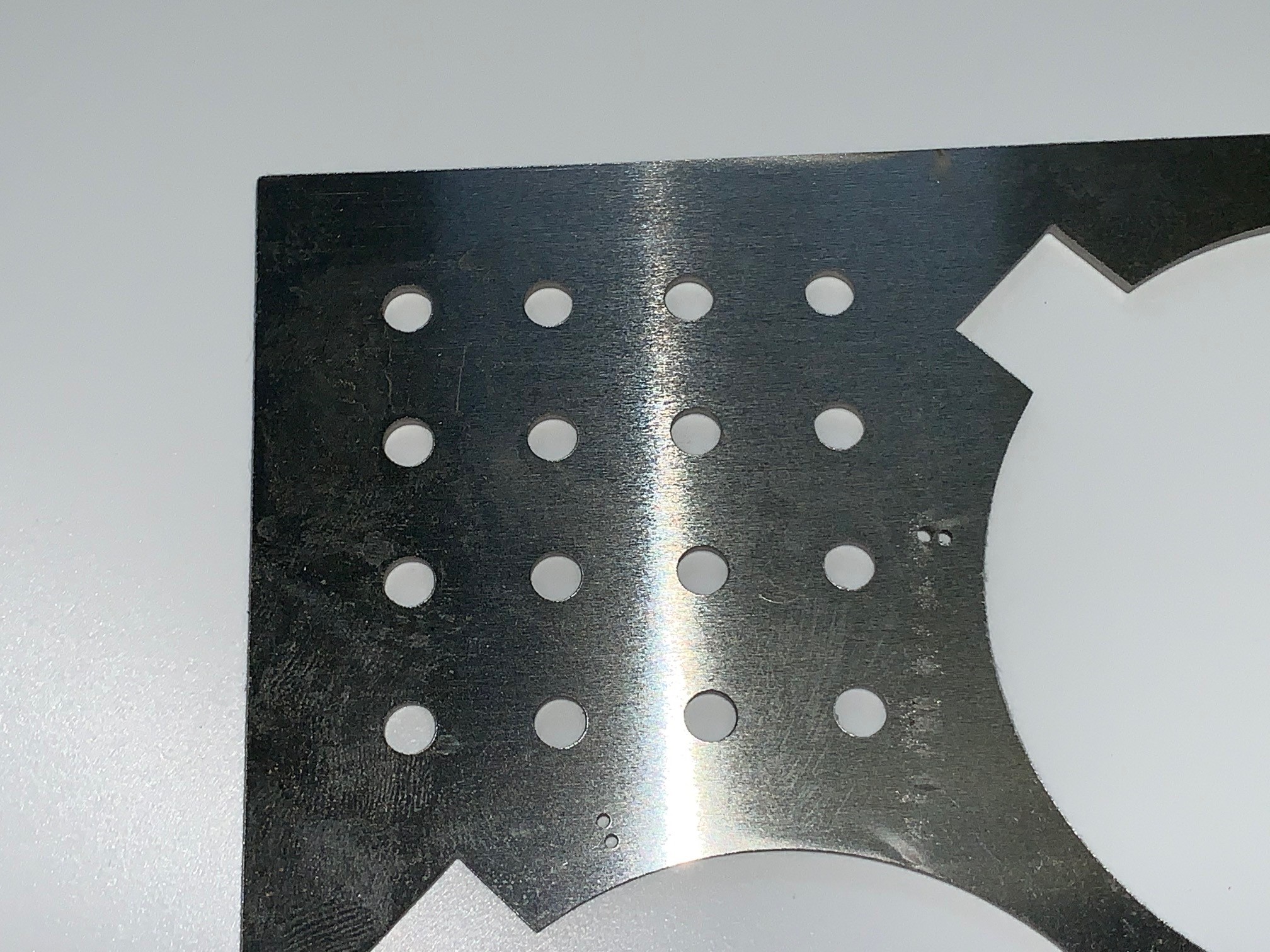

Supra 510 Sheet | Plate

Supra 510 sheets and plates are available in a range of thicknesses and sizes, providing high dimensional stability and flatness. These products are used in precision engineering, aerospace, and scientific instrumentation, where exact dimensions and minimal thermal distortion are essential.

Supra 510 Round Bar | Rod

Supra 510 round bars and rods are offered in various diameters and lengths, suitable for machining into precision parts. These components are crucial for applications requiring tight dimensional tolerances and stability, such as in high-tech manufacturing and precision mechanical assemblies.

Supra 510 Strip | Coil

Available in flexible strips and coils, Supra 510 is used in applications where materials need to be bent, formed, or continuously utilized. These forms are especially valuable in the production of precision springs, connectors, and components requiring both flexibility and dimensional stability, applicable in electronics, automotive, and high-precision machinery.

Supra 510 Applications

-

<

- In structural components, support and substrates require precision measurements such as optical and laser systems, telescopes, laser bench tops, and ring gyroscopes.

Supra 510 Properties

- Coefficient of Thermal Expansion: Approximately 1.0 x 10-6 /°C, which is very low compared to most metals, making Supra 510 suitable for high-precision applications.

- Density: Around 8.0 g/cm³, offering a balance of strength and weight that is advantageous for various industrial applications.

- Thermal Conductivity: Approximately 10-12 W/m·K, providing moderate thermal conductivity while maintaining dimensional stability.

- Magnetic Properties: Generally ferromagnetic, which may be relevant in applications where magnetic properties need to be considered or managed.

- Mechanical Properties: Supra 510 offers good mechanical strength and ductility, optimized for dimensional stability rather than maximum strength.

Machining Supra 510

- Cutting: Supra 510 can be cut with conventional tools. It is important to use sharp tools and adjust cutting speeds to prevent excessive wear and achieve clean cuts.

- Drilling: For drilling Supra 510, high-speed steel (HSS) drills or carbide-tipped bits are recommended. Proper lubrication and cooling are essential to maintain tool life and ensure accurate drilling.

- Turning: Carbide inserts are preferred for turning Supra 510. Consistent feed rates and effective heat management are crucial to maintain dimensional accuracy during turning operations.

- Milling: Supra 510 can be milled using conventional techniques. Carbide end mills and cooling fluids should be used to manage heat and prevent dimensional changes during milling.

- Grinding: Grinding Supra 510 is effective for achieving tight tolerances and fine finishes. Use appropriate abrasive wheels and coolant to ensure a high-quality surface finish while preserving dimensional stability.

Chemical Composition

- Carbon (C): Max 0.03%

- Manganese (Mn): Min 0.30%, Max 0.60%

- Silicon (Si): Min 0.15%, Max 0.30%

- Phosphorus (P): Max 0.02%

- Sulfur (S): Max 0.02%

- Nickel (Ni): Min 49%, Max 51%

- Copper (Cu): Max 0.20%

- Iron (Fe): Balance

| Material | Form | Size Inches | SKU Number |

|---|---|---|---|

| SUPRA 510 | Sheet | Thickness: 0.010" to 0.500"; custom widths and lengths | SUPRA510-SHEET-0.125-12x12 |

| SUPRA 510 | Plate | Thickness: 0.500" and up; custom sizes | SUPRA510-PLATE-0.750-24x24 |

| SUPRA 510 | Bar/Rod | Diameter: 0.250" to several inches; length up to 36" or more | SUPRA510-BAR-1-36 |

| SUPRA 510 | Tube/Pipe | Diameter: 0.5" to several inches; custom wall thickness | SUPRA510-TUBE-1-0.125 |

| SUPRA 510 | Wire | Diameter: 0.010" to 0.250"; often supplied in coils | SUPRA510-WIRE-0.050-100 |

| SUPRA 510 | Custom Fabrications | Custom dimensions and shapes as required | SUPRA510-CUSTOM-FAB-001 |