ELGILOY, also known as UNS R30003 or ASTM F1058, is a high-performance cobalt-based alloy renowned for its exceptional combination of strength, corrosion resistance, and high-temperature stability. It is recognized under W.NR.2.4711 and DIN 17744, which ensures adherence to rigorous international quality standards.

ELGILOY is engineered for demanding applications that require superior mechanical properties and resistance to harsh environments. Its composition offers excellent resistance to oxidation, corrosion, and wear, making it suitable for use in high-stress and high-temperature conditions.

Elgiloy Sheet | Plate

ELGILOY sheets and plates are available in a range of thicknesses and dimensions, providing versatility for various applications. These materials are commonly used in the aerospace industry, medical devices, and other critical components requiring high strength and resistance to environmental factors.

Elgiloy Round Bar | Rod

ELGILOY round bars and rods are available in various diameters and lengths, ideal for precision machining and manufacturing components that must withstand significant mechanical stresses and corrosive environments.

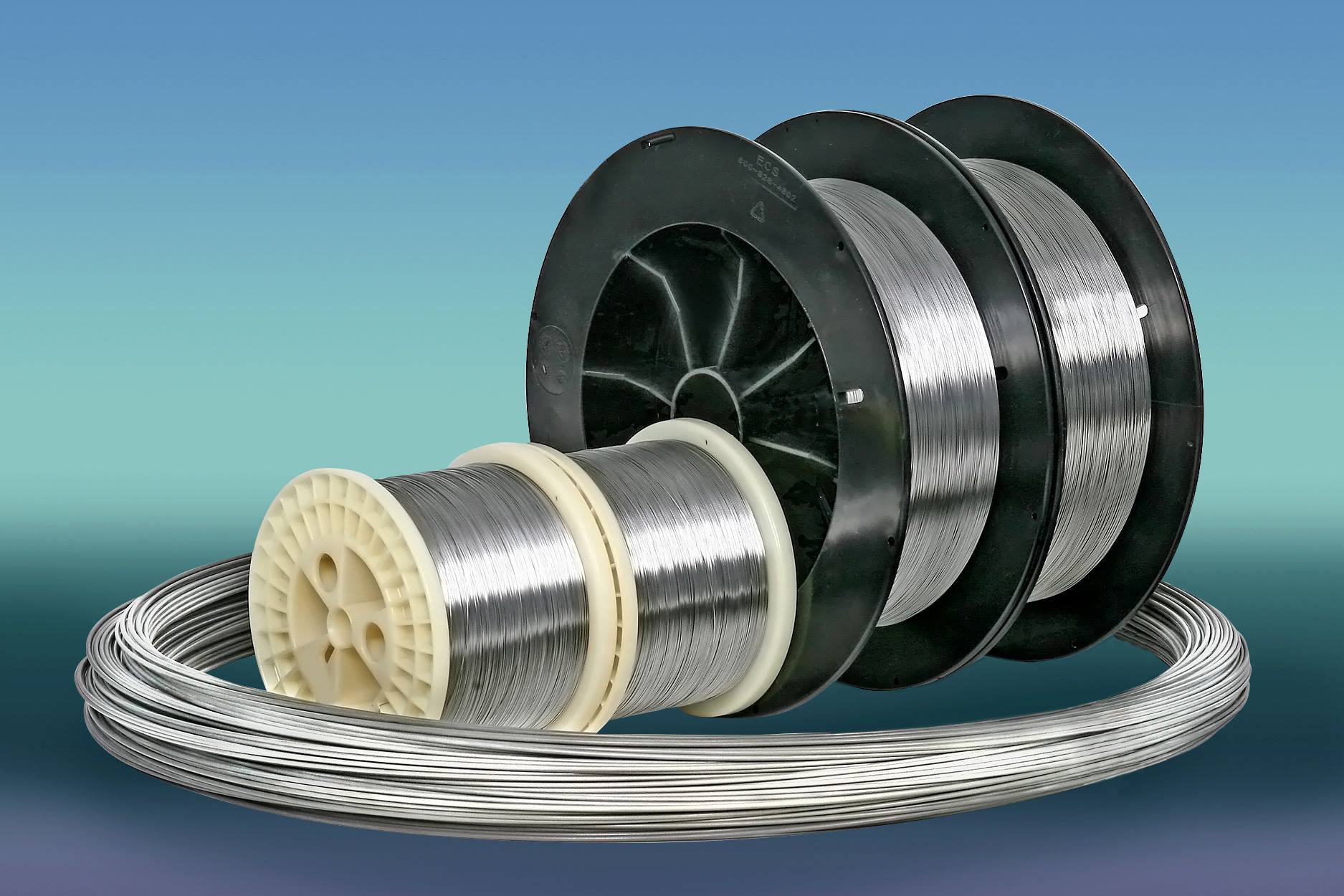

Elgiloy Strip | Coil

Offered in strips and coils, ELGILOY is suited for applications requiring flexibility and high strength. These forms are often used in the production of springs, seals, and other components that need to maintain their properties under severe conditions.

Elgiloy Applications

- ELGILOY is used in aerospace components where high strength and resistance to extreme temperatures are critical.

Elgiloy Properties

- Tensile Strength: ELGILOY exhibits high tensile strength, making it suitable for demanding applications requiring robustness and durability.

- Density: Approximately 8.6 g/cm³, offering a favorable strength-to-weight ratio for various industrial uses.

- Thermal Conductivity: Moderate thermal conductivity ensures stability and performance under elevated temperature conditions.

- Corrosion Resistance: Excellent resistance to corrosion and oxidation extends the lifespan of components in harsh environments.

- Wear Resistance: Superior wear resistance is beneficial for applications involving high friction and mechanical stress.

Machining Elgiloy

- Cutting: ELGILOY can be cut using carbide tools or high-speed steel. Techniques such as water jet cutting or laser cutting are recommended for precision applications.

- Drilling: Utilize carbide drills for drilling ELGILOY. Adequate cooling and lubrication are essential to maintain tool life and ensure accurate drilling.

- Turning: Carbide inserts are preferred for turning ELGILOY. Consistent cutting speeds and high-pressure cooling are crucial for optimal results.

- Milling: Milling operations should use carbide end mills with sufficient cooling to manage heat and maintain precision.

- Grinding: For grinding ELGILOY, diamond or CBN wheels are recommended to achieve precise tolerances and a high-quality surface finish. Proper cooling is necessary to prevent overheating and maintain dimensional accuracy.

Chemical Composition

- Cobalt (Co): Min 39%, Max 41%

- Chromium (Cr): Min 19%, Max 21%

- Nickel (Ni): Min 14%, Max 16%

- Molybdenum (Mo): Min 6%, Max 8%

- Manganese (Mn): Min 1.5%, Max 2.5%

- Iron (Fe): Balance

- Silicon (Si): Max 1.2%

- Carbon (C): Max 0.15%

- Beryllium (Be): Max 0.1%

- Phosphorus (P): Max 0.015%

- Sulfur (S): Max 0.015%

| Material | Form | Size Inches | SKU Number |

|---|---|---|---|

| ELGILOY | Sheet | Thickness: 0.020" to 0.500"; custom widths and lengths | ELGILOY-SHEET-0.125-12x12 |

| ELGILOY | Plate | Thickness: 0.500" and up; custom sizes | ELGILOY-PLATE-0.750-24x24 |

| ELGILOY | Bar/Rod | Diameter: 0.250" to several inches; length up to 36" or more | ELGILOY-BAR-1-36 |

| ELGILOY | Tube/Pipe | Diameter: 0.5" to several inches; custom wall thickness | ELGILOY-TUBE-1-0.125 |

| ELGILOY | Wire | Diameter: 0.010" to 0.250"; often supplied in coils | ELGILOY-WIRE-0.050-100 |

| ELGILOY | Custom Fabrications | Custom dimensions and shapes as required | ELGILOY-CUSTOM-FAB-001 |